Project planning, engineering and production of high quality contact strips and contact parts is the core competency of PanTrac. A special focus of the Berlin company is on the constant and intensive further development of the products in partnership with the manufacturers of vehicles and pantographs worldwide. Close collaboration with the world-market leading pantograph manufacturers in the Wabtec Group (Stemmann, Faiveley, Transtec, Brecknell Willis, Austbreck) offers technical and technological advantages.

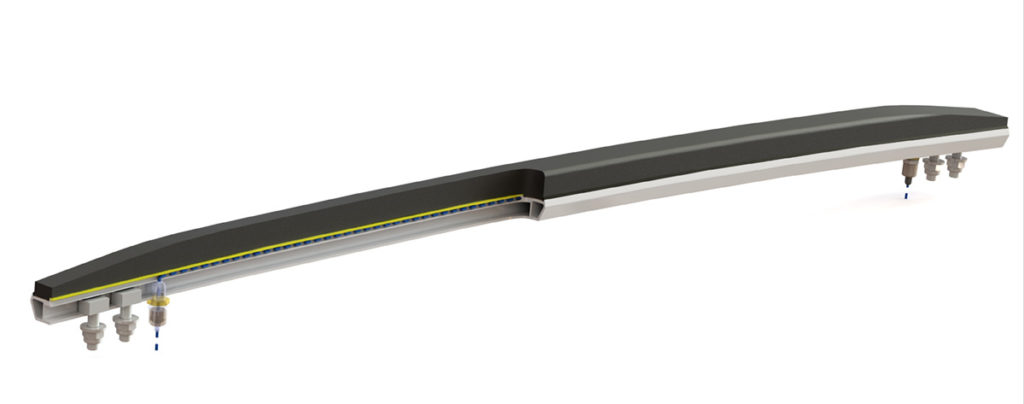

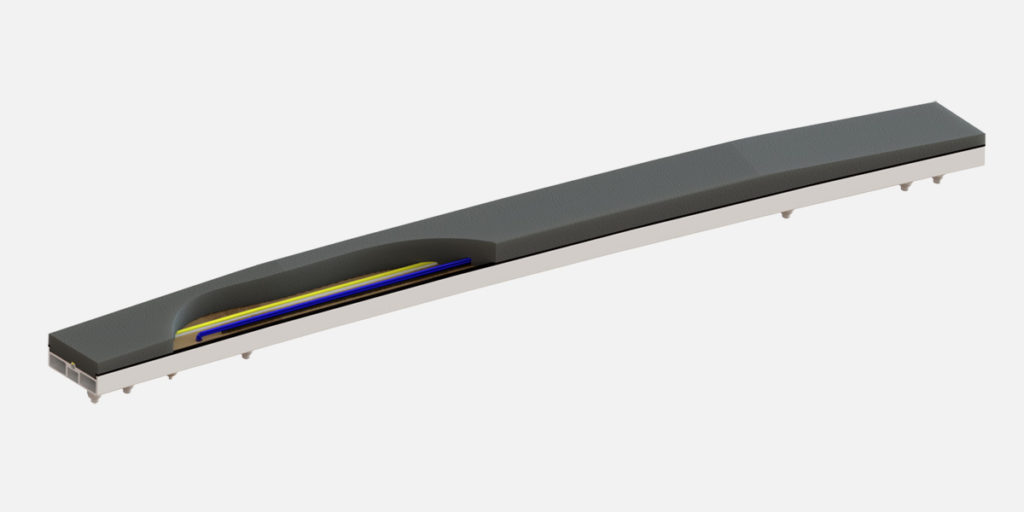

With the result of reliable and efficient energy transmission under all operating conditions: PanTrac components for electrical traction units are characterized by the long service life of the carbon material and maximum protection of the contact partner as well as by high current-carrying capacity and temperature resistance thanks to the use of a unique adhesive system for pantograph applications and 3rd rails.

The PanTrac safety technologies, such as the automatic dropping system ADD and the arc protection APD ensure the highest operational safety even for the most demanding applications and on all continents.

- For every type of AC- and DC-applications

- High speed

- High current DC

- Metro/Urban Transport

- LRV/Tram

- Trolley bus

Optional equipment

The automatic dropping system ADD from PanTrac is a global standard for operational safety.

The highly effective system reacts particularly quickly and sensitively to damage to the contact strips and offers optimum safety especially in high-speed applications.

The accelerated automatic dropping of the pantograph reliably protects against consequential damage to catenary systems and vehicles.

Weather conditions such as heavy rain, hoarfrost and ice cause intensive arcing between the contact wire and the pantograph. These arcs endanger the stability of the mechanical support profiles and force the contact strips to be replaced prematurely.

With the arc-resistant APD technology from PanTrac, corresponding failures, e.g. on the Swedish state railway line, could be reduced by more than 95 percent.

The reliability and availability of the vehicles is the top priority for vehicle operators, but external influences, such as ice formation on the overhead line, can severely disrupt the operating process.

Here, Faiveley offers optional wear monitoring, which can report unexpectedly high wear of the carbon material in real-time.

Selected references

FULL LINE

DB, ÖBB, SBB, SJ, Green Cargo, VR, NS, SNCF, CR, PRASA, CD, PKP, GBR, Korail, TRA

COMMUTER/METRO/LRV/TROLLEY

London DLR, San Francisco MUNI, Translink Vancouver, VBL, BVG, KVB, VBK, VAG, NJT, MTR HK, Salzburg AG

If you are interested in detailed information please contact our product managers

Information request

You can request detailed information using the following contact form.